Magnetizing Fixtures

We can produce simple two-pole axial coils in varying sizes to best utilize the available energy of your magnetizer, depending on what material you are working with, or complex multipole / Halbach field distributions to create a specific magnet.

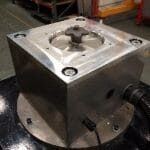

Axial Field Solenoid Fixture

Axial Field Solenoids generate a high magnetic field along the bore of the fixture. As most sintered rare earth magnets are anisotropic, these fixtures are perhaps the most common fixture used in the magnetization industry. The big advantage they can be used for any shape of magnet as long it will fit within the bore of the solenoid with the direction of magnetization in line with the axis of the coil. As the space around the fixture is not limited as with a multipole fixture, very high fields can be generated if necessary, in excess of 5T.

Depending on the length of the solenoid, multiple magnets can be magnetized on one go, or magnets can be fed into the coil using a continuous feed system. Although most fixtures have a round bore, square or rectangular solenoids can be designed for specific shaped magnets.

Applications

- 2 Pole magnets or assemblies

- Loud speaker magnets or assemblies

Features

- Standard coils for Ferrite, NdFeB or SmCo materials

- Not magnet shape restricted

- Compatible with continuous feed Systems

Options

- Water or air cooling available

- Over Temperature Trips

Exterior Radial Multipole Fixture

Exterior radial multipole magnetizing fixtures are designed to produce a multipole radial field on the external diameter of a ring magnet or magnet assembly such as a permanent magnet rotor. They are optimized to produce a sharp a pole transition as possible within the constraints of the magnet size or pole number.

The big advantages are that permanent magnet rotors can be assembled un-magnetized avoiding safety and issues with the handling high energy magnets, and significantly reducing assembly times. Multipole fixtures can be used on permanent magnet rotors that are sleeved, or constructed from either anisotropic or isotropic magnets, sintered radial rings or pre-aligned segments.

Applications

- Ring Magnets

- Permanent Magnet Rotors

- Post Assembly Magnetization

Features

- Minimum pole pitch typically 3mm

- Optional skewed magnetization

Options

- Water or air cooling available

- Over Temperature Trips

- Magnet positional sensors

- Inbuilt search Coils for online magnet testing

Internal Radial Multipole Fixture

Internal radial multipole magnetizing fixtures are designed to produce a multipole radial field on the internal diameter of a ring magnet or magnet assembly such as the rotor of an exterior rotor permanent magnet machine, permanent magnet stators or flywheels. They are optimized to produce a sharp a pole transition as possible within the constraints of the magnet size or pole number.

The big advantages are that permanent magnet assemblies can be assembled un-magnetized avoiding safety and issues with the handling high energy magnets, and significantly reducing assembly times. Multipole fixtures can be used on assemblies that are constructed from either anisotropic or isotropic magnets, radial rings or pre-aligned segments. They can also be used to re-magnetize assemblies that have been thermally demagnetized.

Applications

- Ring Magnets

- Permanent Magnet Rotors or Stators

- Flywheels

- Post Assembly Magnetization

Features

- Minimum pole pitch typically 3mm

- Optional skewed magnetization

Options

- Water or air cooling available

- Over Temperature Trips

- Magnet positional sensors

- Inbuilt search Coils for online magnet testing

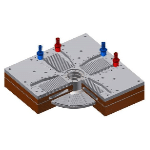

Axial Field Multipole Fixture

Axial field multipole magnetizing fixtures are designed to produce a multipole axial field on the face of a ring, disc or block magnet. They are particular suitable for many applications from axial field permanent magnet rotors to sensors or encoders discs with high pole numbers. Very high precision or very small pole pitches refer to our range of Fine Pole Pitch Magnetizing Fixtures. They are optimized to produce a sharp a pole transition as possible within the constraints of the magnet size or pole number.

Very thick magnets, or magnets where the magnetic field strength is required on both opposing faces, double sided axial field fixtures can be used where the fixture coils are placed above and below the magnet faces.

Applications

- Ring or disc magnets

- Axial field permanent magnet rotors

- Sensors or encoders

Features

- Minimum pole pitch typically 3mm

Options

- Water or air cooling available

- Over Temperature Trips

Homopolar / Radial Fixture

Radial or Homopolar magnetizing fixtures are designed to produce a single radial pole on the inner and outer diameters of a ring magnet. They are in essence constructed from two opposing axial field solenoids, such that the opposing flux is forced radially outwards in the region between the two coils.

The consequence of having two opposing coils is that they both generate very high opposing forces which try and force the coils apart. In addition, the magnitude of the field in the centre of each coil is significantly higher than in the magnet region and so the mechanical construction of these fixtures is paramount. It is not surprising that these fixtures have been known to be called ‘bucking coils’ as they can jump around of not mechanical restrained.

Not all magnets are suitable for radial magnetization. The ideal shape is a washer shape magnet where the length to diameter ratio is small. The longer the magnet is, the more distorted the radial field becomes and the higher the higher fields in the centre of the coil need to be to fully saturate the full length of the magnet. Further information on this can be found in the attached technical paper.

Applications

- Sintered radial ring magnets

- Isotropic ring magnets

- Linear Actuators

- Passive magnetic bearings

Options

- Water or air cooling available

- Over Temperature Trips

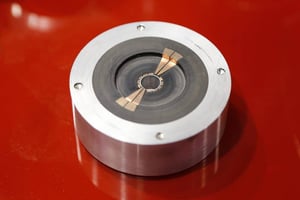

Fine Pole Pitch Magnetizing Fixture

Fine pole pitch magnetizing fixtures are specifically designed for applications, such as encoders and sensors, which require pole pitches less than 3mm, or multiple sensor tracks on a single component.

The windings are CNC machined to achieve a high level of accuracy and designs are continuously been developed to push the minimum pole pitch to the sub 1mm level. For best performance, fine pole pitch magnetizing fixtures should be operated by magnetizers custom designed to generate very fast current pulses.

Applications

- Multipole sensors / encoders

- Single / multiple tracks

Features

- Pole pitch typically 1 - 3mm

Options

- Water or air cooling available

- Over Temperature Trips

Prototype Magnetizing Fixture

Research and development work often requires small numbers of magnets for prototyping or testing at different stages of the development of a new product. Simple 2 pole magnets can always be magnetized in one of our own standard solenoids fixtures but any multipole magnet usually requires a dedicated magnetizing fixture. To avoid the cost of a production magnetizing system, Bunting Magnetics can build prototype fixtures which will be magnetically same as a production unit, but may be manufactured from less hard wearing materials and will be without all the cooling and normal fixture interlocks. These fixtures can only be used at Bunting Magnetics and have a limited lifetime, but will be available for use by the customer for the duration of a project.

Benefits

- Low volume sample runs

- Fast turn-around times available

- Magnetically the same as production units

- Ideal for research or product development

Halbach Magnetising Fixture

Halbach multipole magnetising fixtures differ from conventional multipole fixtures in that they are designed specifically to produce a Halbach magnetisation distribution in the permanent magnet material or assembly. They are best suited to magnetising isotropic magnets where the direction of magnetisation is defined by the magnetising fixture rather than the anisotropy of the magnet, however they can also be used for quasi-halbach permanent magnet assemblies constructed from un magnetised anisotropic magnet segments.

Halbach fixture multipole designs can be applied to radial, axial or planar magnet fixture designs.

Benefits

- Halbach Magnetisation

- Sinusoidal airgap flux density

- Low Cogging Torque

- Reduced Total Harmonic Distortion

- Post assembly magnetisation

Features

- Minimum pole pitch typically 3mm

- Optional skewed magnetisation

Options

- Water or air cooling available

- Over Temperature Trips

- Magnet positional sensors

- Inbuilt search Coils for online magnet testing

Get Started Today

Let's work together to scale your manufacturing.