Magnetizing & Testing

Magnetization is the process whereby a permanent magnet material is exposed to a high intensity magnetizing field in order to drive the material into saturation and develop the full permanent magnetic properties. The strength of the magnetizing field needed is considerably higher than the intrinsic properties of the material and depends primarily on the type of material being magnetized. The older permanent magnetic materials such as AlNiCo’s and Ferrites are relatively easy to magnetize as they only require magnetic fields in the region of 1Tesla which can be generated by a number of methods such as DC electromagnets and even permanent magnet magnetizers. The rare earth magnets on the other hand, mainly Neodymium or Samarium Cobalt, require much higher fields in the range of 3 to 5Tesla. Although it is possible to generate DC magnetic fields of this magnitude using super conducting magnets, it is not yet practical or cost effective for industrial or laboratory situations. Consequently, most magnetizing systems utilize capacitor discharge technology to generate a magnetic pulse of sufficient strength to magnetize the material, but of short enough duration to prevent the magnetizing coils from overheating.

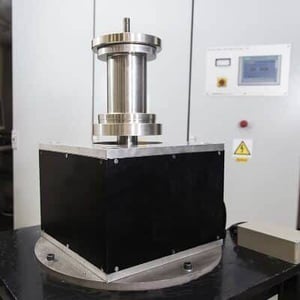

A BMC Industrial Magnet Charger designed & built by Bunting for an Italian customer

Magnetizing Systems & Fixtures

A typical Magnet Applications magnetizing system consists of a capacitor discharge magnetizer, a magnetizing fixture and sometimes an additional automatic handling system. We manufacture both magnetizers and fixtures in the UK to our own standard design or to custom customer designs.

Magnetizing fixtures are generally custom designed for each application, and therefore should be the first thing to consider when purchasing a magnetizing system. Fixtures can be supplied with many different types of magnetization patterns from simple 2 pole solenoids, to complex multipole systems. As a long time manufacturer of permanent magnets, in particularly bonded Neodymium ring magnets, Magnet Applications have been manufacturing magnetizing fixtures for our own internal use for many years, and have developed a particular area of expertise in the design of multipole magnetizing systems for radial or axial ring magnet assemblies or sensor magnets.

Our magnetizers come in a number of standard ranges for use in laboratories, small scale production environments or large scale industrial applications. Magnetizers typically have two output voltage ranges dependent on the type of magnetizing fixture being used. Low voltage systems, usually up to 1000V, are ideal applications where the speed of the magnetizing pulse is less critical, such as for magnetizing large blocks of magnet material or magnetic assemblies such as loud speaker magnets where it may be important to limit eddy currents in the magnets or surrounding steel work. High Voltage systems, usually up to 3000V, but occasionally 5000V, are better for multipole applications or high energy magnetizing systems where temperature control in the windings is important and the magnetization pules therefore need to be as fast as possible.

Bunting Magnetizer control and magnetizing fixture

Get Started Today

Let's work together to scale your manufacturing.